Nutriciel is an automation and production management solution (MES) dedicated to the sector of feed. With its modular design, Nutriciel perfectly adapts to your factory's layout.

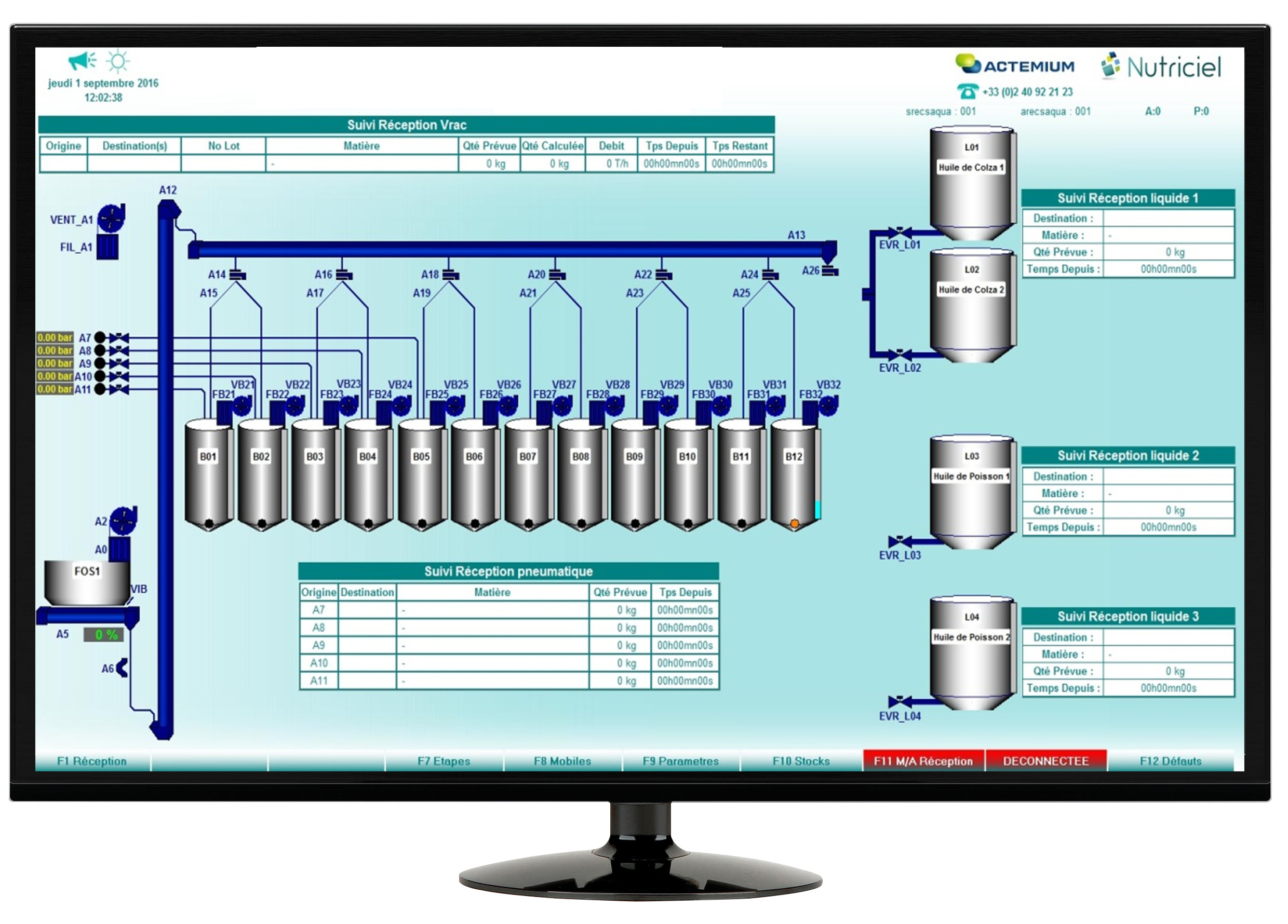

Through dynamic supervision, you monitor and control the processes of your production unit.

All throughout your processes, Nutriciel records and safeguards all your data, ensuring complete traceability.

Nutriciel supports your current and future performance.

NEW IN 2017 !

Monitor your production indicators thanks to a series of widgets.

Nutriciel addresses your challenges

YOUR INDUSTRIAL FACILITIES ARE OPTIMISED AND EFFICIENT

Nutriciel increases your productivity by optimising your resources. You monitor your stock levels in real time and can anticipate your orders. Your production costs are thus reduced.

YOUR PRODUCTION IS IN LINE WITH YOUR CLIENTS' REQUIREMENTS

Nutriciel ensures compliance with quality specifications through the traceability of raw materials and processes. All operations are recorded and traced. Data are available and can easily be viewed from the Nutriciel interface.

YOUR INVESTMENTS ARE PROTECTED

Nutriciel is a sustainable solution benefiting from the support of a strong and powerful group. Thanks to a team of experts fully dedicated to animal nutrition, our software changes to meet your needs, frequently offering new features to help improve your performance.

The Nutriciel concept : you are independent in a secure environment

Nutriciel is accessible to everyone: all operators at their own level have control over settings and operations

You work independently: Nutriciel can be used with all automated and computerised systems; no adaptations are necessary.

With Nutriciel, your events are managed. You meet your clients' traceability requirements and comply with legal requirements. All actions are recorded, traced and secure. All your data are stored in a secure environment and can easily be accessed.

- Scalable, custom development

- Scheduling optimisation

- Traceability of materials, products and operations

- Energy consumption data

- Single point of data entry

- Optmised maintenance costs

- Bag warehouse management

- Dashboards and statistics