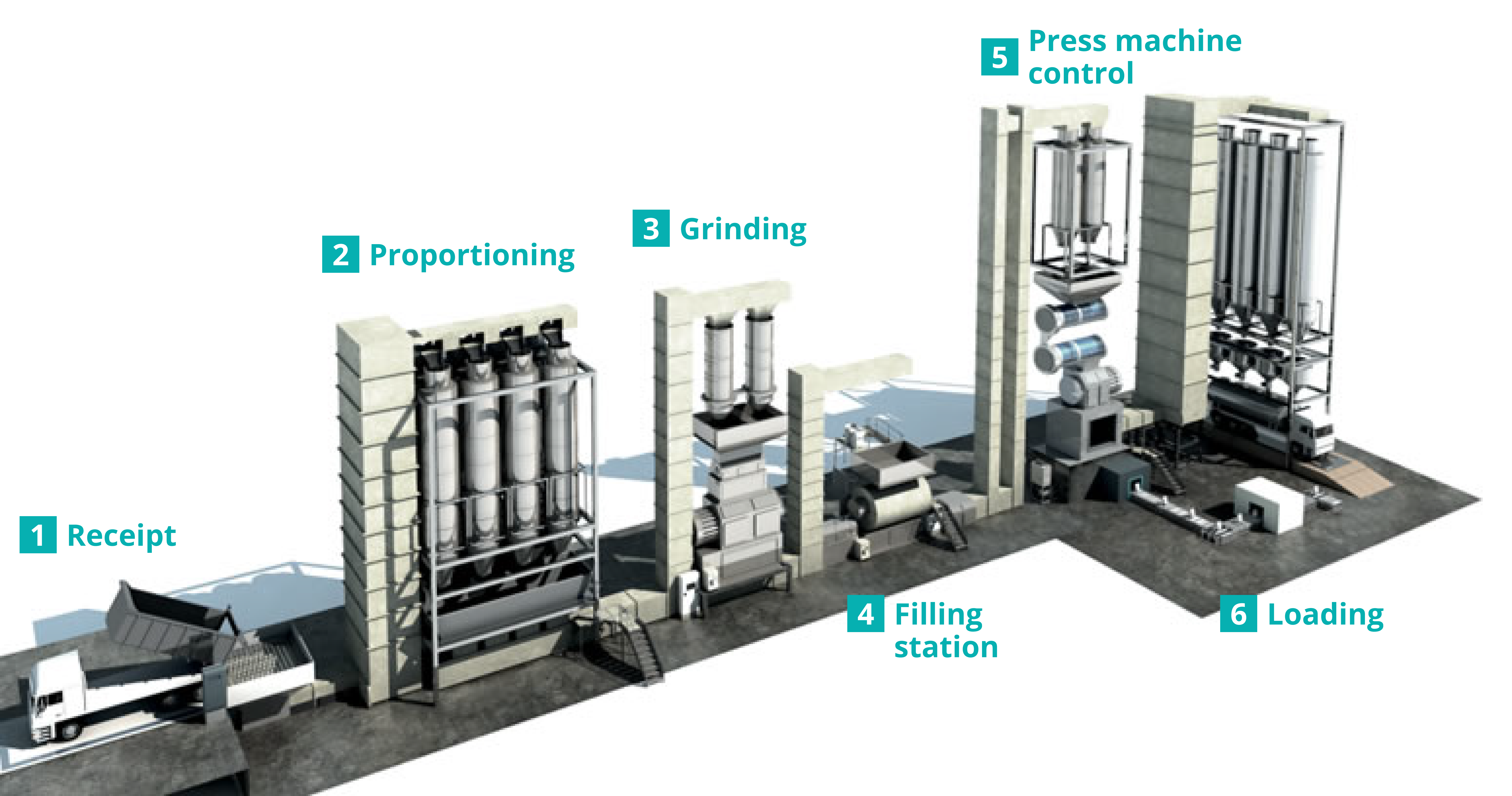

Control your site

From receipt to delivery, in bags or in bulk, Nutriciel automates all of your processes.

- Receipt

This first stage involves receiving bulk or bagged raw materials, whether bulk blown or still liquid. Cereals are weighed and stored. Upon arrival of the lorries, Nutriciel traces all operations and products. - Proportioning or production

Raw materials are proportioned in keeping with your recipes, which have been saved in Nutriciel. - Grinding : before or after proportioning, cereals are ground to varying degrees of fineness, as requested by your clients.

- Filling station : very small quantities of ingredients are added at the filling station. Although the operator performs this step manually, it is monitored and safeguarded by Nutriciel.

- Granulation : with Nutriciel, the pressing machine runs autonomously. Ingredients are stored in hoppers and then pressed to extract pellets. Sifting may be performed in order to sort the generated pellets. As an option, the pellets may be crumbled and/or coated.

We propose Cpr 500, a solution that manages only the granulation machine (feeder, mixer and press) for any type of processor or press machine, with the addition of up to 4 liquids.

Loading

Nutriciel allows you to ship your finished products, whether in bulk or in bags. Our solution covers the loading of lorries and the management of delivery slips, always with optimum traceability

Receipt

This first stage involves receiving bulk or bagged raw materials, whether bulk blown or still liquid. Cereals are weighed and stored. Upon arrival of the lorries, Nutriciel traces all operations and products.

Proportioning or production

Raw materials are proportioned in keeping with your recipes, which have been saved in Nutriciel.

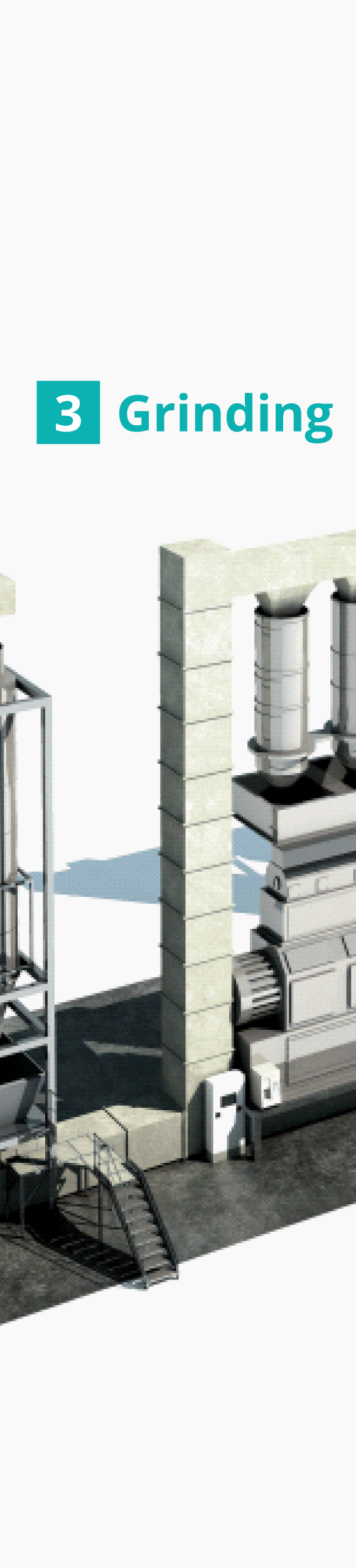

Grinding

Before or after proportioning, cereals are ground to varying degrees of fineness, as requested by your clients.

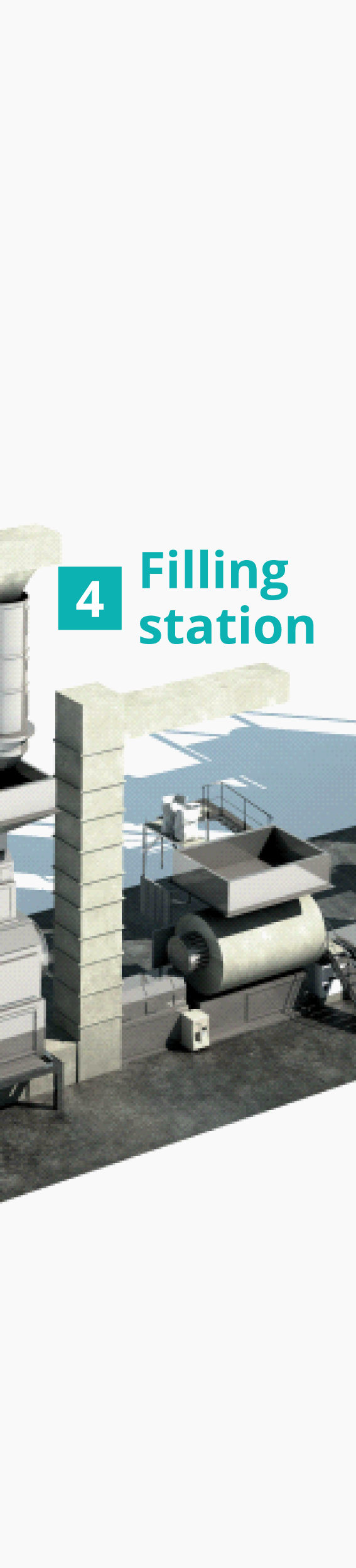

Filling station

Very small quantities of ingredients are added at the filling station. Although the operator performs this step manually, it is monitored and safeguarded by Nutriciel.

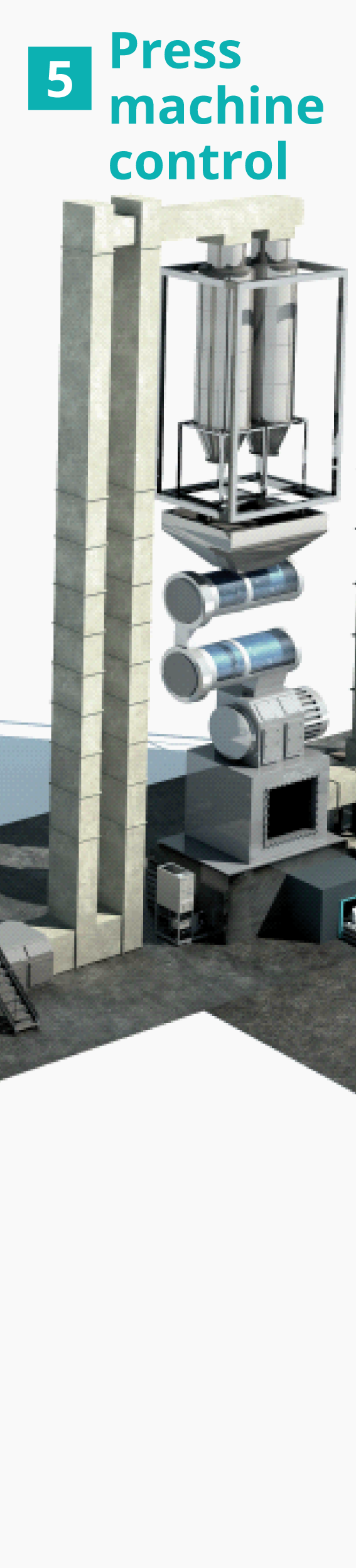

Granulation

With Nutriciel, the pressing machine runs autonomously. Ingredients are stored in hoppers and then pressed to extract pellets. Sifting may be performed in order to sort the generated pellets. As an option, the pellets may be crumbled and/or coated.

LOADING

Nutriciel allows you to ship your finished products, whether in bulk or in bags. Our solution covers the loading of lorries and the management of delivery slips, always with optimum traceability

We propose Cpr 500, a solution that manages only the granulation machine (feeder, mixer and press) for any type of processor or press machine, with the addition of up to 4 liquids.

Loading

Nutriciel allows you to ship your finished products, whether in bulk or in bags. Our solution covers the loading of lorries and the management of delivery slips, always with optimum traceability